Ipayipi le-alloy lensimbi engenamthungo yepayipi le-alloy eliphikisana nokushisa okuphezulu kanye nesakhiwo sepayipi ye-alloy pressure

Incazelo Yomkhiqizo

Amapayipi engxubevange anezingxenye ezingenalutho futhi asetshenziswa kakhulu njengamapayipi okuthutha uketshezi, njengamapayipi okuthutha uwoyela, igesi yemvelo, igesi, amanzi, imishini, nezinye izinto eziqinile.Uma kuqhathaniswa nensimbi eqinile njengensimbi eyindilinga, ipayipi lensimbi ye-alloy linesisindo esilula uma ukugoba kwalo namandla okugoqa kuyafana.Ipayipi lensimbi ye-alloy iyinsimbi yesigaba sezomnotho, esetshenziswa kabanzi ukwenza izingxenye zesakhiwo kanye nezingxenye zemishini, njengepayipi lokubhoboza uwoyela, umshini wokuhambisa imoto, uhlaka lwebhayisikili kanye nesikafula sensimbi esisetshenziswa ekwakheni.Ukwenza izingxenye zendandatho ngepayipi lensimbi ye-alloy kungathuthukisa izinga lokusetshenziswa kwezinto, kube lula inqubo yokukhiqiza, konga izinto zokwakha kanye namahora okucubungula, njengeringi elithwalayo, umkhono kajack, njll. Njengamanje, ipayipi lensimbi selisetshenziswe kabanzi ekukhiqizeni.Ipayipi yensimbi ye-alloy nayo iyinto ebaluleke kakhulu yazo zonke izinhlobo zezikhali ezijwayelekile.Isibhamu kanye nomgqomo kufanele kwenziwe ngepayipi lensimbi.Ipayipi lensimbi ye-alloy lingahlukaniswa libe yipayipi eliyindilinga kanye nepayipi elimise okukhethekile ngokuya ngendawo ehlukene ye-cross-sectional kanye nokuma.Ngenxa yokuthi indawo eyindilinga inkulu kakhulu ngaphansi kwesimo somjikelezo olinganayo, uketshezi oluningi lungathuthwa ngepayipi eliyindilinga.Ukwengeza, lapho isigaba sendandatho singaphansi kokucindezela kwe-radial yangaphakathi noma yangaphandle, amandla afana kakhulu.Ngakho-ke, amapayipi amaningi ensimbi angamapayipi ayindilinga.Amapayipi engxubevange ahlanganisa amapayipi engxubevange anobubanzi obukhulu, amapayipi alloy odongeni awugqinsi, amapayipi alloy anomfutho ophezulu, ama-alloy flanges, izindololwane zealloy, amapayipi alloy P91 namapayipi ensimbi angenamthungo.Ngaphezu kwalokho, amapayipi akhethekile omanyolo wamakhemikhali nawo avame kakhulu.

Ipharamitha Yomkhiqizo

| Ima | I-GB/T8162 ASTM A53 ASME SA53I-JIS DIN |

| Ibanga lepayipi lensimbi | 16Mn 12Cr1MoV T91 27SiMn 30CrMo 15CrMo 20G Cr9Mo 10CrMo910 15Mo3 15CrMoV 35CrMoV 45CrMo 15CrMoG,12Cr2MoG,12Cr1MoVG,12Cr2MoWVTiB,10Cr9Mo1VNb,I-SA210A1,SA210C,I-SA213 T11,I-SA213 T12,I-SA213 T22,I-SA213 T23,I-SA213 T91,I-SA213 T92,ST45.8/Ⅲ,13CrMo44 |

| Ubude | okugoqiwe okushisayo (okunwetshiwe futhi kwanwetshwa): 3-12m okugoqiwe okubandayo (okudwetshiwe): 2-10.5m |

| Ububanzi bangaphandle | okugoqiwe okushisayo: 32-756mm / kubanda okudonswe: 5-200mm |

| ukujiya kodonga | 2.5-100mm |

| Isevisi Yokucubungula | Ukusika noma ngokwesidingo sekhasimende |

| Imininingwane yokupakisha | Ukupakisha okungenalutho/ikesi lokhuni /indwangu engangeni manzi |

| Imigomo Yokukhokha | T/TL/C |

| 20 izinyawo isiqukathi iqukethe ubukhulu | Ubude obungaphansi kuka-6000mm/25T |

| Isiqukathi esingamamitha angu-40 siqukethe ubukhulu | Ubude obungaphansi kuka-12000mm/27T

|

| Amasampula | Amasampula wamahhala anikeziwe kodwa impahla ikhokhelwa umthengi |

| I-oda elincane | 1Ton |

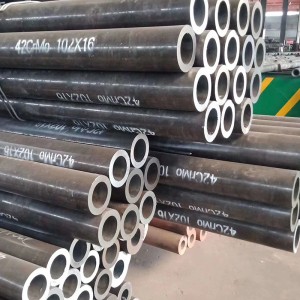

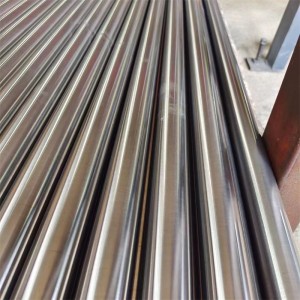

Umbukiso Womkhiqizo

Amasevisi Okucubungula

Inzuzo

Inkampani yethu inenani elikhulu lokusungula, ingahlangabezana nezidingo zakho ngesikhathi.

hlinzeka ngolwazi olufanele ngesikhathi ngokwesidingo sekhasimende sokuqinisekisa inani nekhwalithi yemikhiqizo.

Ngokuthembela emakethe yensimbi enkulukazi yezwe, indawo eyodwa nayo yonke imikhiqizo oyidingayo ukuze ulondoloze izindleko.

Isicelo somkhiqizo

Amashubhu engxubevange asetshenziselwa kakhulu ukushisisa amashubhu angaphezulu kwama-boilers anengcindezi ephansi naphakathi (ingcindezi yokusebenza ngokuvamile ayingaphezu kuka-5.88MPA futhi izinga lokushisa lokusebenza lingaphansi kuka-450 ℃);Isetshenziselwa ukushisisa amapayipi angaphezulu, ama-economizers, ama-superheaters, ama-reheaters namapayipi embonini ye-petrochemical yama-boilers anengcindezi ephezulu (ingcindezi yokusebenza ngokuvamile ingaphezulu kuka-9.8MPa futhi izinga lokushisa lokusebenza liphakathi kuka-450 ℃ ~ 650 ℃).Ngakho-ke, amashubhu e-alloy asetshenziswa kabanzi ku-petroleum, i-aerospace, imboni yamakhemikhali, amandla kagesi, i-boiler, imboni yezempi nezinye izimboni.

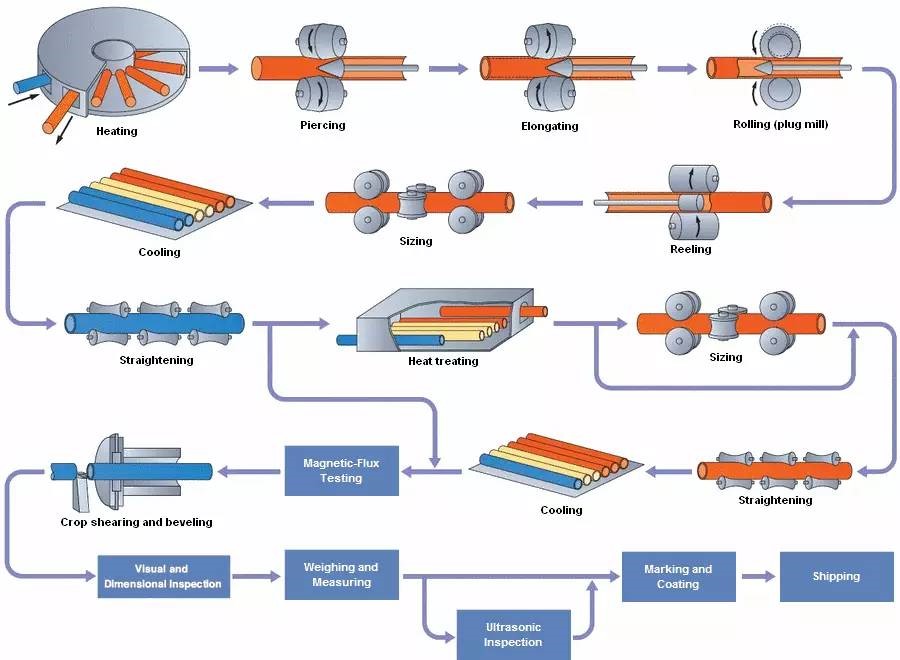

Inqubo Yokukhiqiza